An article for InterBrew magazine: By Alexey Makoveev, EP Minerals’ area sales manager for Russia and Julie Brown

Here in Russia, we really like our beer. (And our vodka, but that’s another subject.) But we don’t think much about how beer is made and what makes it better. How do you make the best beer? Is the ingredients? The hops, the malt, the barley? The recipe? The brewer? The fermenting process? Is it in how you store it?

What I can tell you after working with top brewers all over Russia and other countries, is that the key to great beer comes down to one thing: Filtration.

Why filter?

First of all, why do we filter in the first place? Before the 20th century, people drank beer out of pewter tankards or stoneware – they didn’t look at what they were drinking. However, the wealthier people at the time started drinking out of glasses, and that became the popular trend. Drinking from clear glasses, better lighting, and modern shelf displays, all drove attention to filtration clarity. Everyone wanted crystal clear beer that tasted really good. Only recently has there been a return to an acceptance of less than bright beers as evidenced by the growth of local craft brew and wheat beers.

Throughout history, even dating back to 1500 BC, there have been plenty of filter aids that have been used to filter beer – crushed beach shells, crushed carcasses of shrimp, cockroaches, locusts & beetles, coconut fibers, peanut shells and rice husks. Sounds delicious. Today’s beer filtration is a little more refined.

The challenge of creating crystal clear beer

Two hundred years ago, it was possible to produce a crystal clear beer, but it wouldn’t stay that way for long. The original process relied on sedimentation and decantation. Finings, substances like isinglass (swim bladders of fish), Irish moss and egg whites were used, and centrifugal separators have been used to take out the yeast. All of those filtration processes were limited and cumbersome.

Brewers today need to remove impurities or particles in beer, down to the micron and submicron “haze” in the liquid. To do this without finings, you have to resort to filtration. Surface filtration with cartridges, sheets or bag filters may work fine for other liquids, but these other approaches lack the capacity and flexibility to filter commercial volumes of beer.

Filter aid filtration, more technically called dynamic depth filtration, usually employs diatomaceous earth (DE) or kieselguhr as the filtration medium, and is the most cost-effective and flexible technology for clarifying beer, and it is the only true renewable filtration process used today in the brewing industry.

EP Minerals' diatomaceous earth

EP Minerals' diatomaceous earth

What is diatomaceous earth or kieselguhr?

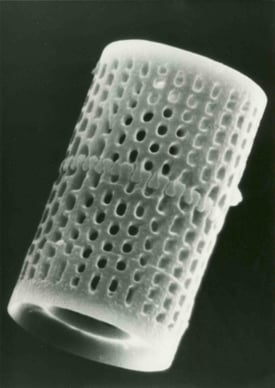

Diatomaceous earth consists of the skeletal remains of microscopic unicellular plants which lived in the past, and live today, in fresh and salt water lakes and oceans. Huge deposits of these diatom frustules are found in certain parts of the earth that were covered by lakes at one time, like Nevada. The fresh water diatoms that EP Minerals harvests are from the Melosira granulata species. It’s unique, strong, cylindrical geometry, high pore volume, and low resistance to flow makes it an excellent filter medium for beer.

A microscopic view of a single diatom

A microscopic view of a single diatom

Choosy brewers choose diatomaceous earth

Beer making, and therefore beer filtration, is an industrial process that relies upon agricultural materials. Because it uses agricultural raw materials, which can have a significant variation in characteristics, the filtration requirements for beer can also vary much more than the characteristics of manufactured liquids. DE and dynamic depth filtration are adaptable, and flexible. They allow brewers to easily adjust their filtration to their own particular brewing standards which brings out the true “personality” of their beer, and, of equal importance, DE and dynamic depth filtration can be easily adjusted to match the natural changes that can occur within agricultural raw materials. DE allows brewers to use their professional and artistic skills to get the most out of their beer. DE is also chosen because it’s inert, it’s a good value, it’s readily available and because of its high efficiency and high throughput.

Loading trucks with diatomaceous earth at EP Minerals' Lovelock mine

Loading trucks with diatomaceous earth at EP Minerals' Lovelock mine

Challenges with a membrane filtration system

Recent studies have shown that a membrane filtration system will significantly increase water and energy costs, simply because of how the technology works. Membrane filters are complex to operate and require special equipment and products for sanitizing. Membrane filters can strip flavor and foam characteristics from the beer and are also prone to fouling, decreasing flux rate and leaking problems. Another issue is that membrane filters remove specific sized particles based on the size of the aperture in the surface membrane installed, so there isn’t the adaptability that brewers like to see with a DE filter, allowing for changes.

Most importantly, as mentioned above, it is very simple to adjust the loading of the DE filtration medium in a dynamic depth filtration system to match changes in the agricultural raw materials used in brewing. This is not possible with a membrane system that contains absolutely fixed pore sizes.

Filtering beer is difficult

The most difficult particles to remove from a liquid are those that are small (submicron) and biological in nature (soft and compressible). Very small particles are not really solid particles at all but are in a grey area of being partly solubilized macromolecules. In beer, some of these are important as they contribute to the foam stability, the color and texture of the brew and what’s called “mouth feel.” Other small particles cause haze and instability and need to be retained in the filter. The problem with a system (membrane) which is 100% based on particle size is that important components can be lost – components that add to the taste and “personality” of the beer. DE filtration and dynamic depth filtration provide for a flexible semi-selective process that allows for the partial, rather than absolute, removal of important taste components of the beer.

Beer filtration and sustainability

At EP Minerals, we believe that the recycling of organic and inorganic materials is central to achieving healthy soils, clean water, and a sustainable society. We are actively helping our customers recycle our minerals. In breweries, after filtering the beer, the customer is left with a by-product called “spent cake.” We’ve worked diligently with many of our customers to identify local sustainable alternatives to recycling the spent cake instead of it ending up in a landfill. We are successfully helping our customers everywhere to re-direct spent DE filter cake into compost, fertilizer, and other environmentally-desirable applications. Learn more about EP Minerals' Commitment to Sustainable Solutions

It is not generally recognized, but it is also true that diatomaceous earth, itself, is a renewable agricultural product that is constantly being produced in the world’s lakes and oceans. Although the time between the growth of EP Mineral’s DE “crop” and harvesting can be thousands or even millions of years, each day that we mine (or harvest) our crop, trillions of diatoms worldwide are growing and reproducing.

So, you can rest assured that these tiny critters are still with us and that we would be in a serious world of hurt if they weren’t, as they produce between 70-80% of the world’s oxygen.

While, as a Russian, it is hard for me to admit, when it comes to oxygen, the diatom even grealy outproduces all of the trees of the Russian taiga, the Amazon rain forest and all other land plants combined.

Choosing a filter aid

EP Minerals produces Celatom® and Celabrew® natural DE filter aids in full range of grades with different degrees of permeability to meet different brewers’ specific requirements. Celatom is our standard grade product. The lower permeability grades form filter cakes, having small pores which produce a high degree of clarification. The higher permeability grades have larger pores and provide increased throughput. Celabrew has reduced soluble iron, which can increase beer shelf life and stability.