Diatomaceous earth is truly incredible. Every day we find a new use or application for our DE. This week, UC Riverside engineering professors announced that they're using DE as a source of silica for electric car battery anodes. Hello, Elon Musk and Mr. Panasonic!

Most people who believe in the electric car revolution would agree with this statement: “Batteries that power electric vehicles are expensive and need to be frequently charged, which causes anxiety for consumers and negatively impacts the sale of these vehicles. To improve the adoption of electric vehicles, we need much better batteries.”

Those are the words of Mihri Ozkan, a professor of electrical engineering at the University of California – Riverside’s Bourns College of Engineering. He and his colleague Cengiz Ozkan, a professor of mechanical engineering at UCR, have recently published a paper in the journal Scientific Reports entitled “Carbon-Coated, Diatomite-Derived Nanosilicon as a High Rate Capable Li-ion Battery Anode.” Mihri Ozkan says, “We believe diatomaceous earth, which is abundant and inexpensive, could be another sustainable source of silicon for battery anodes.”

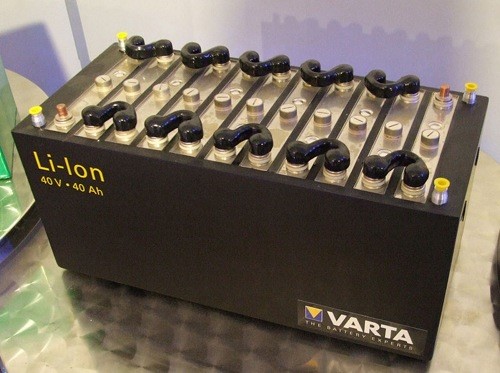

Lithium ion batteries, the most popular rechargeable batteries in electric vehicles and personal electronics, have several major components including an anode, a cathode, and an electrolyte made of lithium salt dissolved in an organic solvent. The anode and cathode are the electrodes that connect the storage medium to the outside world. Better electrodes make better batteries. End of story.

The professors have previously investigated using portabello mushrooms and beach sand to make better anodes for batteries. Their latest research delves into the possibility of using the fossilized remains of single-cell algae called diatoms. If their research is correct, the diatoms could be the key to less expensive, more energy efficient silicon-based anodes for lithium ion batteries.

Today, graphite is the material of choice for most anodes. It is cheap, but electrodes made from graphite have limited performance. Silicon, which can store about 10 times more energy, is being developed as an alternative anode material. The problem is that the traditional way of manufacturing it, called carbothermic reduction, is expensive and requires lots of energy.

To change that, the UCR team turned to a cheap source of silicon—diatomaceous earth (DE)—and a more efficient chemical process. DE is an abundant, silicon-rich sedimentary rock that is composed of the fossilized remains of diatoms deposited over millions of years. Using a process called magnesiothermic reduction, the group converted this low-cost source of silicon dioxide to pure silicon nano-particles.

“A significant finding in our research was the preservation of the diatom cell walls—structures known as frustules—creating a highly porous anode that allows easy access for the electrolyte,” Cengiz Ozkan says.

Every report about a breakthrough in the lab has to be accompanied by a disclaimer. Thousands of researchers are spending millions of dollars in search of better batteries. Some of the parameters being addressed are weight, cost, energy density, size, and power. There is a new “breakthrough” announced every few days, it seems.

One day not too far in the future, batteries for electric cars will be half the size, half the weight, half the cost, and have twice the energy density of today’s batteries. No one discovery will make all of that happen. The UCR news may be part of the story. We will have to wait and see whether this is real of just more vaporware.

Thanks to Steve Hanley at Gas2 blog for his good, information post!